'*************************************

' Description:

' Configuration of the A-axis for BLDC. Feedback is a digital encoder with TTL.

' Various values must be adapted for the respective drive/controller constellation!

' DMC

' Brushless DC servo motor without Halls

'*************************************

' General configuration

'*************************************

#AUTO ;' With this jump label the program already starts when switching on

MG "General configuration"

ST ;' Stop all axes if something is still running

WT 1000 ;' Wait 1 second

MO ;' Switch off the control for all axes, they are now free to move

IA 192,168,9,111 ;' Define IP address

TM 250 ;' Here we define the sample rate to 250 ms

'*************************************

' Axis configuration

'*************************************

MG "Initialization start"

MT 1 ;' Motor type is a servo, with -1 you can change the direction

'CE 0 ;' or also with the CE command

TL 1 ;' Set the current/torque limitation for the continuous value

TK 9.99 ;' Set the current/torque limitation for the peak value

AG 0 ;' Set the current amplification in the controller, different depending on the drive

AU 0 ;' AG and AU are also dependent on the inductance of the drive

;' For calculation see manual in the appendix.

'Initialization of sine commutation with BX with limited travel,

'so that the motor ideally moves max. 15 degrees. A current peak is applied to the motor

'to fix the position of the rotor or to adjust the commutation.

BAA;' Configure axis A for sine commutation

BMA=1333.3333;' Encoder pulses per revolution / number of pool pairs

' Important: Always specify all 4 decimal places!

BX<1000;' Hold time in milliseconds (duration of the current peak)

BXA=3;' Activate motor briefly with 3 V control signal

' (motor current [A] = motor control signal [V]* amplification [A/V])

'Define PID values for axis A

KD 60;' Differential component (influence on damping)

KP 6;' Proportional component (influence on dynamics)

KI 0.1;' Integral component (influence on positioning accuracy)

IT 1;' If this filter was active, first reset to default

AC 1073740800 ;'Acceleration, maximum

DC 1073740800 ;'Deceleration, maximum

SP 10000 ;'Initial speed

DP 0 ;'Sets the motor position counter to 0

WT 1000 ;'Wait 1s

MG "Configuration ready"

'*************************************

' Main program

'*************************************

'Move to starting position

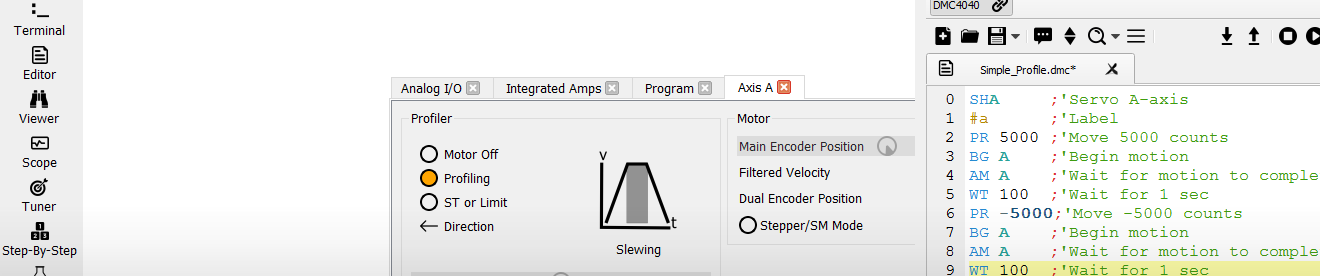

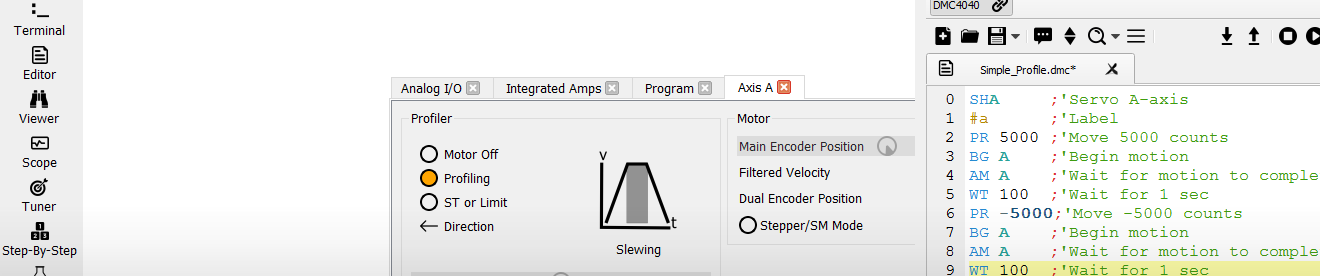

SHA ;' Axis A switch on the control loop/servo controller

PAA=1000 ;' Move to position 1,000 inc absolute move command

BGA ;' Start move command

AMA ;' Wait until move command is finished

MG "Pos. is: ",TP, " ink"

EN ;' End of program